use of v notch in impact test|astm notched impact testing : bulk The Charpy Impact Test, also known as a V-notch test, evaluates a material’s impact strength by measuring the energy required to fracture a standardized sample with a machined V-notch. Using a released pendulum, . WEBr/Maria_Cerejinha: Maria Cerejinha. mari cerejinha youtube sentando na rola com força, safada puxou a fio dental de lado e sentou com vontade,

{plog:ftitle_list}

Cerejinha @MariaCerejinha. Dançarina Cerejinha ASSINATURAS. Assinar (1 mês) R$ 100,00 / mês Outras Opções Voltar PACOTES. 3 Meses. Assinar R$ 300,00 . 6 Meses. Assinar R$ 600,00. Já tenho Cadastro. Crie sua conta: Nome do Perfil. E-mail. CPF. Nome Completo. Data de Nascimento. Senha. Sua senha deve conter no mínimo 8 caracteres .

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact test results help manufacturers and engineers determine whether the material is suitable for its .

The Charpy V Notch (CVN) test is a basic method for defining toughness and, in this process, toughness is defined in “joules or ft lbs” at the “temperature of test”. There are other, more complex methods but the CVN test is cheap, is a good .

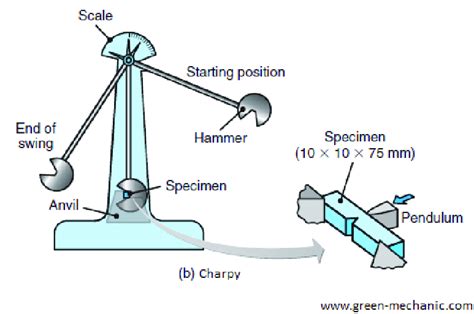

Charpy impact testing, or V-notch testing, is an evaluation of a material’s strength and performance under impact conditions. It involves a pendulum with a pointed hammer on the end swinging and hitting a machined .

The Charpy Impact Test, also known as a V-notch test, evaluates a material’s impact strength by measuring the energy required to fracture a standardized sample with a machined V-notch. Using a released pendulum, .A widely employed method for assessing weld toughness and impact resistance is the Charpy test, also known as the Charpy V-notch test. This article provides an in-depth exploration of . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure In the Charpy impact test, a notched specimen is .The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the .

4.5 The Charpy V-notch impact test as a powerful tool for delivery control in steel specifications Four types of impact testing are described in detail below, encompassing the pendulum, drop-weight, and dynamic tear methods: 1. Charpy. The Charpy impact test, also known as the V-notch test, is a type of impact .

To successfully perform a Charpy V-notch impact test, the following steps must be followed for accurate results: 1. Notch test specimens. The standard size of a specimen for Charpy impact testing is 10 mm × 10 .Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step .Impact test specimen types include notch configurations such as V-Notch, U-Notch, Key-Hole Notch, as well as Un-notched and ISO (DIN) V-Notch, with capabilities of impact testing sub size specimens down to ¼ size. IZOD Impact Testing can be done up to 240 foot-pounds on standard single notch and type-X3 specimens. Charpy Impact Test

The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient . The impact engineers want to know when a material favours brittle fracture, some materials are ductile in a specific range of temperature, but they still fail like brittle material, why ? presence of stress risers, high rate of strain . , by bringing the notch they promote the condition of brittle fracture and the notch provides three . The Charpy impact test, sometimes called a V-notch test, is a comparative-style test used to define a material’s impact strength by determining how much energy is required to fracture a pre-prepared and standardized sample with a . The most common notch geometry today is the V-notch, but other geometries are or have been sometimes used. Depending on notch geometry, the test is known as the Charpy-V impact test (CVN) or Charpy-U impact test (CUN) or even Charpy-keyhole. The U-notch has normally a radius of 1 mm, compared to the V-notch which has a root radius of 0.25 mm.

Eyeshadow Powder moisture meter

U- and V-notched specimens for impact testing require precision and compliance with standards. It starts with selecting the appropriate material, taking into account its properties and the specific parameters of the test standards. The material is then cut to exact dimensions using advanced tools like CNC machines and precision cutters.As was written, toughness can be measured by the Charpy test or the Izod test.These two standardized impact tests, the Charpy and the Izod are used to measure the impact energy (sometimes also termed notch toughness). The Charpy V-notch (CVN) technique is most commonly used.

• V-notch – A V-shaped notch, 2mm deep, with 45° angle and 0.25mm radius along the base • U-notch or keyhole notch – A 5mm deep notch with 1mm radius at the base of the notch. What Does the Charpy Test Involve? The Charpy test involves striking a suitable test piece with a striker, mounted at the end of a pendulum.

The resulting test sample measures 80 x 10 x 4 mm. The depth under the notch of the specimen is 8mm. Data: ASTM impact energy is expressed in J/m or ft-lb/in. Impact strength is calculated by dividing impact energy in J (or ft-lb) by the thickness of the specimen. The test result is typically the average of 5 specimens.

Anti-Itch Powder moisture meter

Charpy test sample with a notch. In mechanical engineering and materials science, a notch refers to a V-shaped, U-shaped, or semi-circular defect deliberately introduced into a planar material. In structural components, a notch causes a stress concentration which can result in the initiation and growth of fatigue cracks. Notches are used in materials characterization to .The V-notch maker and impact test machine are displayed in Fig. 1.4 [8]. The impact strength is determined by the loss of energy of the pendulum as determined by precisely measuring the loss of height in the pendulum's swing [9]. Researchers also defined impact strength as the tendency of polymer composites to endure high-energy impact without .The ASME Impact Test Requirement I4I Academy LLC article provides information about impact test requirement in pressure vessel design and construction. . temperature, if it is proved by conducting Charpy V-notch . The Charpy Impact Test, also known as the Charpy V-notch test, is a crucial method in the field of materials testing. This test helps determine a material’s ability to absorb energy and resist breakage under high-velocity .

This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D .Mechanical testing - Notched bar or impact testing - Part I. The previous article looked at the method of Charpy-V impact testing and the results that can be determined from carrying out a test. This next part looks at the impact testing of welds and some of the factors that affect the transition temperature such as composition and microstructure.A widely employed method for assessing weld toughness and impact resistance is the Charpy test, also known as the Charpy V-notch test. This article provides an in-depth exploration of the Charpy test, covering aspects such as the test machine, specimen preparation, temperature variations, test results, and the advantages of this evaluation .Charpy testing machine, a rod of mild steel and a rod of carbonate steel. Charpy Test Specimens. Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be : V-notch – A V-shaped notch, 2mm deep, with 45° angle and 0.25mm radius along the base.

v notch impact test

The most common notch geometry today is the V-notch, but other geometries are or have been sometimes used. Depending on notch geometry, the test is known as the Charpy-V impact test (CVN) or Charpy-U impact test (CUN) or even Charpy-keyhole. The U-notch has normally a radius of 1 mm, compared to the V-notch which has a root radius of 0.25 mm.The Charpy V notch test, or Charpy impact test, measures the energy absorbed by a material during fracture. The destructive test method consists of a pendulum, hammer, and a beam of metal placed between two anvils. The energy required to fracture the material provides insight into the material’s notch toughness at various temperatures.

The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which are useful in engineering design, analysis of structures, and materials development. EQUIPMENT • Charpy V-notch test specimens of 6061-T6 aluminum and 1018 (hot rolled) or A36 steelTensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test.An impact test consists of a striker hitting the test specimen to transfer a large force in a short time.You can use a drop tower or a pendulum tester to achieve such large forces.. A striker is dropped vertically from a height for a drop tower test and uses gravity to achieve the necessary impact energy. Similarly, in a pendulum test, the striker is fixed to an arm that swings like a . A notched Izod impact test specimen is considered to be properly prepared when it has a few features. Foremost, the v-notch should be centered and machined uniformly so that it satisfies the required size as well as angle dimensions stated in either ASTM D256 or ISO 180 standard methods. Next, its surface must appear smooth without any .

A Charpy impact test, also known as the Charpy V-notch test, is a destructive method designed to measure the amount of energy that a material can absorb as it fractures. Understanding this helps to predict how the material will react to impact loading and is, therefore, an essential determining factor when assessing if your material is suitable .

notched pendulum impact test

Medical Activated Charcoal Powder moisture meter

Ano. 2023. Pôr do Sol - O Mistério do Colar de São Cajó - Filmes - A série de sucesso da RTP agora em formato de filme. Conhecemos a origem da família Bourbon de Linhaça e .

use of v notch in impact test|astm notched impact testing